Top 7 Mistakes to Avoid When Designing Custom Cabinets

Custom cabinet design can transform your home, but costly mistakes often turn dream projects into expensive headaches. Poor planning, inadequate measurements, and overlooking functionality frequently leave homeowners frustrated with cabinets that don't meet their needs.

The seven most common cabinet design mistakes include ignoring storage requirements, choosing the wrong materials, poor space planning, inadequate lighting consideration, overlooking ventilation needs, incorrect hardware selection, and failing to plan for future maintenance. These errors can add thousands to your project cost and create long-term usability issues.

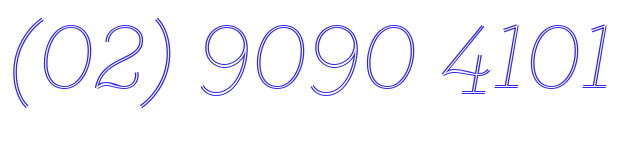

At Sydney Cabinet Makers, we've helped countless Sydney homeowners avoid these pitfalls through proper planning and expert craftsmanship. Understanding these mistakes before you begin ensures your custom cabinets deliver both beauty and functionality for years to come.

Key Takeaways

- Seven critical design mistakes can significantly increase costs and reduce cabinet functionality

- Proper planning and material selection prevent most common cabinet design problems

- Working with experienced cabinet makers helps avoid costly errors and ensures quality results

Understanding the Top 7 Mistakes in Custom Cabinet Design

Custom cabinet design requires careful attention to detail and proper planning. The most common pitfalls involve measurement errors, inadequate storage planning, poor material choices, functional oversights, aesthetic misjudgements, lighting failures, and hardware compromises.

Poor Measurement and Space Planning

Accurate measurements form the foundation of any successful cabinet project. We see clients struggle when they rush this critical first step or rely on rough estimates rather than precise measurements.

Wall irregularities present the biggest challenge in Australian homes. Most walls aren't perfectly straight or square, particularly in older Sydney properties. We always measure at multiple points along each wall to account for these variations.

Ceiling height inconsistencies can derail cabinet installations. Standard ceiling heights vary by 10-20mm across a room. This affects tall pantry cabinets and creates unsightly gaps if not properly planned.

Plumbing and electrical constraints must be mapped precisely. We measure the exact location of pipes, outlets, and switches before finalising designs. Moving these services later adds thousands to project costs.

Appliance dimensions require verification beyond manufacturer specifications. We recommend measuring actual appliances rather than trusting published dimensions, as models can vary slightly.

Overlooking Storage Needs

Storage planning goes beyond simply adding shelves and drawers. We analyse how clients actually use their kitchens to create functional storage solutions through our range of custom kitchen cabinets designed to maximise efficiency and ease of use.

Daily item accessibility drives our design decisions. Frequently used items need easy reach zones between shoulder and waist height. We avoid placing everyday dishes in high cabinets or deep corners.

Specialised storage requirements vary significantly between households. Families with young children need different solutions than empty nesters or cooking enthusiasts.

Common storage oversights include:

- Insufficient spice storage near cooking areas

- No designated space for small appliances

- Inadequate pantry depth for standard containers

- Missing drawer dividers for utensils

- Poor bin placement away from prep areas

Vertical space utilisation often gets ignored. We design cabinets to maximise ceiling height whilst maintaining practical access to upper shelves.

Incorrect Material Selection

Material choices affect both cabinet longevity and daily functionality. Drawing on our experience crafting custom bathroom vanities in Sydney, we guide clients toward materials that perform well in humid environments and handle daily wear. Standard particleboard, for instance, fails quickly around sinks and dishwashers, so we recommend moisture-resistant MDF or plywood for base cabinets in wet areas.

Durability expectations should also match how the space is used. High-traffic family kitchens benefit from heavy-duty hinges and drawer slides, while occasional cooks can often prioritise finishes and aesthetics.

| Material Type | Best Use | Durability | Cost |

|---|---|---|---|

| Solid timber | Display areas | Excellent | High |

| Plywood | Structural components | Very good | Medium-High |

| MDF | Painted surfaces | Good | Medium |

| Particleboard | Budget applications | Fair | Low |

Finish compatibility varies between materials. Some woods accept stain better than others. We test finishes on sample pieces before committing to final selections.

Neglecting Cabinet Functionality

Beautiful cabinets mean nothing if they don't function properly for daily use. We prioritise practical functionality over aesthetic appeal when conflicts arise.

Door swing patterns require careful planning in tight spaces. We map out traffic flows to ensure doors don't interfere with each other or block walkways.

Drawer extension lengths affect usability significantly. Full-extension slides cost more but provide complete access to drawer contents. We rarely recommend partial-extension options.

Internal cabinet depths need standardisation for efficient use. Varying depths create wasted space and complicate organisation systems.

Corner solutions challenge every cabinet designer. We prefer lazy Susans or pull-out systems over traditional fixed shelving that creates dead space.

Soft-close mechanisms aren't just luxury features. They prevent damage from slamming doors and extend cabinet life significantly.

Misjudging Style and Aesthetics

Style choices should complement both the home's architecture and the client's lifestyle. We avoid trendy elements that may look dated within a few years.

Proportional relationships between cabinet elements create visual harmony. Oversized handles on small doors look awkward, whilst tiny knobs disappear on large drawers.

Colour coordination extends beyond cabinet finishes to include benchtops, splashbacks, and appliances. We create cohesive colour schemes that work together long-term.

Hardware consistency throughout the space maintains visual flow. Mixing metals or styles requires careful planning to avoid a chaotic appearance.

Traditional vs contemporary styling should reflect the home's existing architecture. Ultra-modern cabinets rarely suit heritage properties, whilst ornate details look wrong in minimalist spaces.

Ignoring Lighting Integration

Proper lighting transforms cabinet functionality and appearance. We plan lighting integration during the design phase rather than as an afterthought.

Under-cabinet lighting eliminates shadows on work surfaces. We install LED strips inside the front cabinet frame to hide the light source whilst providing even illumination.

Internal cabinet lighting helps with organisation and creates ambiance. Glass-front cabinets particularly benefit from internal lighting to showcase contents.

Electrical planning must occur before cabinet installation. We coordinate with electricians to rough-in wiring whilst walls remain open.

Switch placement affects daily usability. We position switches within easy reach of work areas rather than hiding them behind appliances or in awkward locations.

Cutting Corners on Hardware Quality

Quality hardware investment pays dividends through years of daily use. We never compromise on hinges, drawer slides, or handles despite budget pressures.

Hinge durability directly affects door alignment and operation. European-style hinges with soft-close features cost more initially but prevent door sagging and extend cabinet life.

Drawer slide specifications must match expected loads. We calculate drawer contents weight and select slides with appropriate capacity ratings plus safety margins.

Handle ergonomics matter for daily comfort. We consider grip comfort, mounting strength, and proportional sizing when selecting cabinet hardware.

Finish quality on hardware affects appearance longevity. Cheap finishes wear quickly with regular cleaning and use, particularly in high-traffic areas.

How to Avoid Common Cabinet Design Pitfalls

Proper planning prevents the most costly cabinet design errors that Australian homeowners encounter. Accurate measurements, thoughtful storage planning, and material selection form the foundation of successful custom cabinet projects.

Professional Measurement and Layout

We always take measurements at multiple points along each wall. Walls are rarely perfectly straight, and floors often have slight variations that impact cabinet installation.

Critical measurement points include:

- Wall-to-wall distances at top, middle, and bottom

- Floor-to-ceiling heights at each corner

- Distance from walls to existing plumbing and electrical outlets

- Window and door trim dimensions

We create detailed floor plans before beginning construction. This prevents costly mistakes like blocking electrical outlets or creating doors that cannot fully open.

Ceiling height variations of even 5mm can cause installation problems. We measure these carefully and plan for scribing or filler pieces where needed.

Appliance clearances require precise planning. Dishwashers need 25mm clearance on each side, whilst refrigerators require proper ventilation space at the back and top.

Custom Storage Solutions

We design storage based on what clients actually store rather than standard configurations. Spice racks work better as pull-out drawers than traditional shelves for easy access.

Efficient storage features include:

- Pull-out pantry shelves for deep cupboards

- Corner lazy Susans instead of hard-to-reach corner shelves

- Drawer dividers sized for specific utensils

- Vertical dividers for baking trays and cutting boards

We avoid shelves deeper than 600mm without pull-out mechanisms. Items stored at the back become forgotten and inaccessible.

Height considerations matter significantly. We place frequently used items between 750mm and 1500mm from the floor. Heavy items belong in lower drawers rather than overhead cupboards.

Soft-close hinges and drawer slides prevent damage from slamming. These mechanisms last longer and reduce noise in open-plan homes.

Choosing the Right Materials

We select materials based on Sydney’s humidity levels and the specific room location. In moisture-prone areas like bathrooms and laundries, we use the same construction principles as our custom laundry cabinets — relying on high-grade, water-resistant materials designed for long-term performance. These spaces require moisture-resistant options like marine-grade plywood or moisture-resistant MDF to prevent swelling and warping over time.

Material durability factors:

- Solid timber expands and contracts with humidity changes

- Plywood offers superior strength and stability

- MDF provides smooth surfaces for painted finishes

- Particle board suits budget projects in dry locations only

We avoid particle board in areas exposed to moisture. Steam from kettles or dishwashers can cause swelling and deterioration.

Hardware quality affects long-term performance. We use hinges rated for the weight of doors and contents. Cheap hinges fail within two years under normal use.

Finishes must suit the intended use. High-gloss surfaces show fingerprints easily, whilst matte finishes hide wear better in busy kitchens.

Why Work With Sydney Cabinet Makers?

We combine decades of cabinet-making expertise with deep understanding of Sydney homes to deliver exceptional results. Our team handles every aspect of your project from initial design consultation to final installation.

Expert Advice and Craftsmanship

Our cabinet makers possess over 25 years of combined experience working with Australian hardwoods and European hardware systems. We understand which materials perform best in Sydney's coastal climate and humidity levels.

Each team member holds formal qualifications in cabinet making and joinery. We stay current with industry standards through ongoing professional development and trade association memberships.

Our expertise includes:

- Custom joinery techniques for maximum durability

- Proper timber selection for Australian conditions

- Advanced hardware integration for smooth operation

- Precision measuring and fitting methods

We source materials exclusively from trusted Australian suppliers. Our workshop uses professional-grade machinery including CNC routers and edge banding equipment for consistent quality.

Every cabinet undergoes thorough quality inspection before delivery. We stand behind our work with comprehensive warranties on both materials and workmanship.

Tailored Designs for Sydney Homes

We design cabinets specifically for Sydney's unique housing styles and space constraints. Our team understands the proportions and architectural details of Federation, Art Deco, and contemporary Sydney homes.

Common Sydney home challenges we address:

- Narrow galley kitchens in terrace houses

- Sloping ceilings in converted attics

- Limited storage in small apartments

- Integration with existing period features

We visit your home to measure spaces accurately and assess structural considerations. Our design process accounts for Sydney's building codes and council requirements.

Each design incorporates your specific storage needs and lifestyle requirements. We create detailed 3D renderings so you can visualise the finished cabinets before construction begins.

Our local knowledge extends to understanding which finishes complement Sydney's natural light conditions. We recommend colours and materials that enhance your home's existing character.

End-to-End Project Management

We coordinate all aspects of your cabinet project from initial consultation through final installation. Our project management system ensures clear communication and adherence to agreed timelines.

Our process includes:

- Site consultation and accurate measuring

- Design development and approval

- Material ordering and quality control

- Coordinated delivery and installation

- Final adjustments and cleanup

We handle any required electrical or plumbing coordination with licensed tradespeople. Our installation team arrives with all necessary tools and equipment for efficient completion.

Progress updates occur at key project milestones. We address any concerns immediately and maintain open communication throughout the build process.

Post-installation support includes care instructions and warranty registration. We remain available for adjustments or maintenance questions after project completion.